5 Simple Maintenance Tips That Can Extend Pump Life by Years

In industrial operations, pumps are the unsung heroes—working silently and tirelessly to keep processes running smoothly. Yet, even the most ruggedly built pumps can face premature wear and failures if not maintained properly.

The good news? A little attention and timely care can dramatically extend the lifespan of your pumps, improve reliability, and cut down costly downtime.

At Kakati Karshak Industries, with over six decades of experience in designing and manufacturing Liquid Ring Vacuum Pumps (LRVPs) and complete vacuum systems, we’ve seen firsthand how proper maintenance transforms performance and longevity.

Here are five simple but powerful maintenance tips to ensure your pumps serve you efficiently for years.

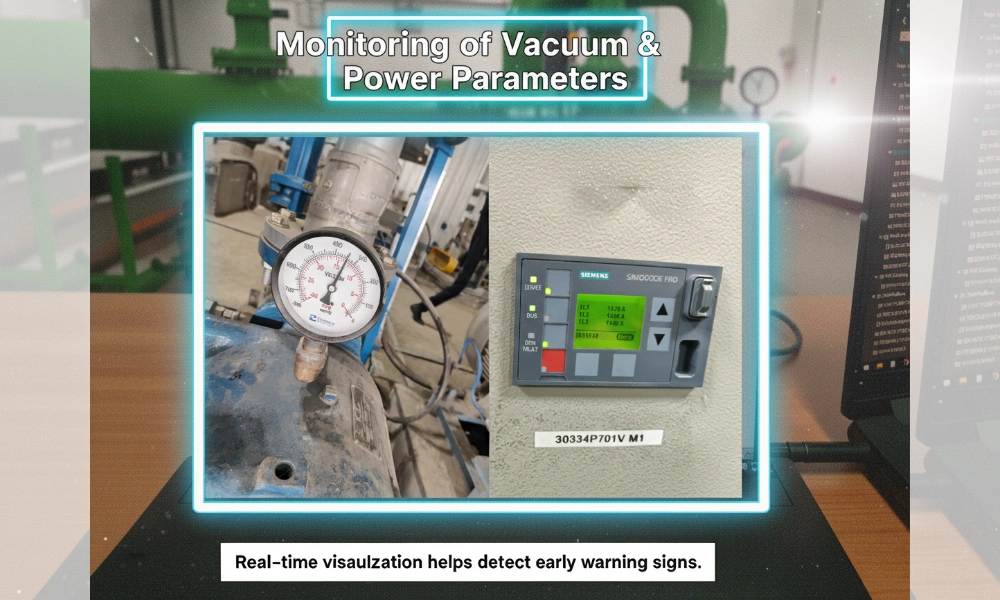

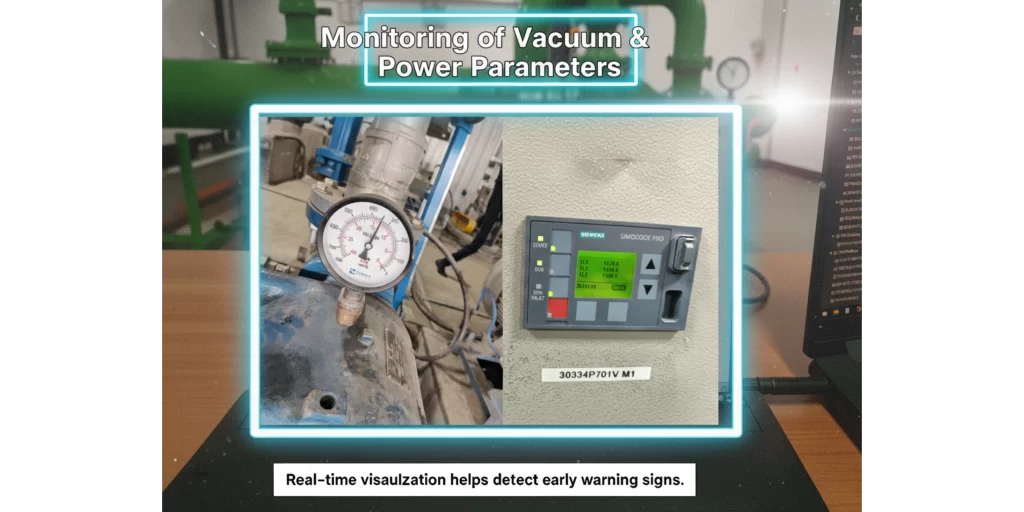

1. Monitor and Maintain Proper Operating Parameters

Every pump is designed to work within specific operating limits—vacuum levels, suction pressure, discharge pressure, and temperature. Running beyond these limits can cause excessive stress on components like bearings, seals, and impellers.

Key checks:

- Monitor vacuum level and power consumption regularly.

- Maintain sealing water temperature within the recommended range (for LRVPs typically 25–35°C).

- Avoid cavitation by ensuring sufficient suction head and proper priming.

Tip: Install gauges and transmitters for real-time performance tracking.

Any deviation from normal trends can signal early issues.

Every pump is designed to work within specific operating limits—vacuum levels, suction pressure, discharge pressure, and temperature. Running beyond these limits can cause excessive stress on components like bearings, seals, and impellers.

Key checks:

- Monitor vacuum level and power consumption regularly.

- Maintain sealing water temperature within the recommended range (for LRVPs typically 25–35°C).

- Avoid cavitation by ensuring sufficient suction head and proper priming.

Tip: Install gauges and transmitters for real-time performance tracking. Any deviation from normal trends can signal early issues.

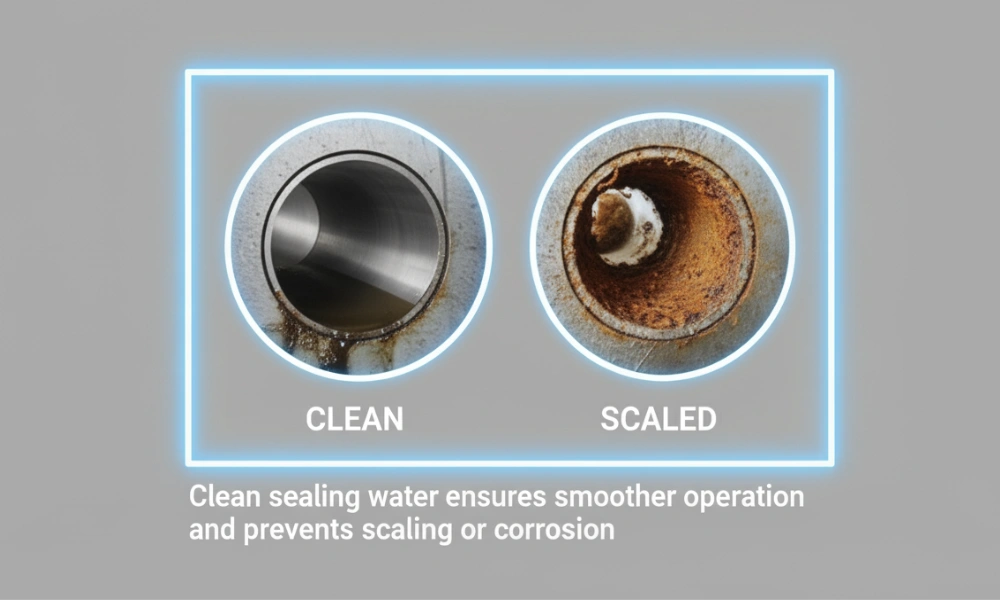

2. Maintain Clean Seal Water and Separator Systems

In liquid ring vacuum pumps, water quality plays a critical role. Contaminated or hard water can cause scaling, corrosion, and reduced sealing efficiency—eventually leading to performance drop and damage.

Best practices:

- Use filtered or treated water to minimize scaling and corrosion.

- Periodically flush the separator and pipelines to remove accumulated debris or oil traces.

- Check separator level and drain system to avoid carryover of water into the process line.

Pro Tip: For continuous duty applications, consider using closed-loop water recirculation systems with cooling and filtration—this reduces water wastage and keeps the system cleaner.

In liquid ring vacuum pumps, water quality plays a critical role. Contaminated or hard water can cause scaling, corrosion, and reduced sealing efficiency—eventually leading to performance drop and damage.

Best practices:

- Use filtered or treated water to minimize scaling and corrosion.

- Periodically flush the separator and pipelines to remove accumulated debris or oil traces.

- Check separator level and drain system to avoid carryover of water into the process line.

Pro Tip: For continuous duty applications, consider using closed-loop water recirculation systems with cooling and filtration—this reduces water wastage and keeps the system cleaner.

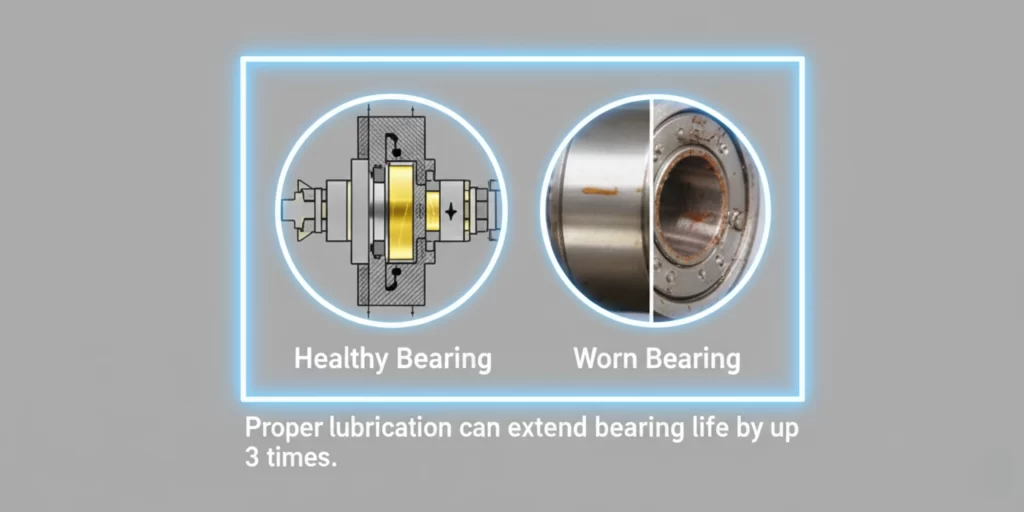

3. Regularly Inspect Bearings and Lubrication System

Bearings are the heart of any rotating equipment. Poor lubrication or contamination is a leading cause of bearing failure.

Recommended checks:

- Monitor bearing temperature and noise regularly.

- Ensure lubrication quality and level are within limits—replace oil at recommended intervals.

- Use manufacturer-approved lubricants and avoid mixing different grades.

- During long shutdowns, rotate the shaft manually to redistribute oil film.

Kakati Tip: For high-performance LRVPs, a clean and well-maintained lubrication system can easily extend bearing life by 2–3 times.

Bearings are the heart of any rotating equipment. Poor lubrication or contamination is a leading cause of bearing failure.

Recommended checks:

- Monitor bearing temperature and noise regularly.

- Ensure lubrication quality and level are within limits—replace oil at recommended intervals.

- Use manufacturer-approved lubricants and avoid mixing different grades.

- During long shutdowns, rotate the shaft manually to redistribute oil film.

Kakati Tip: For high-performance LRVPs, a clean and well-maintained lubrication system can easily extend bearing life by 2–3 times.

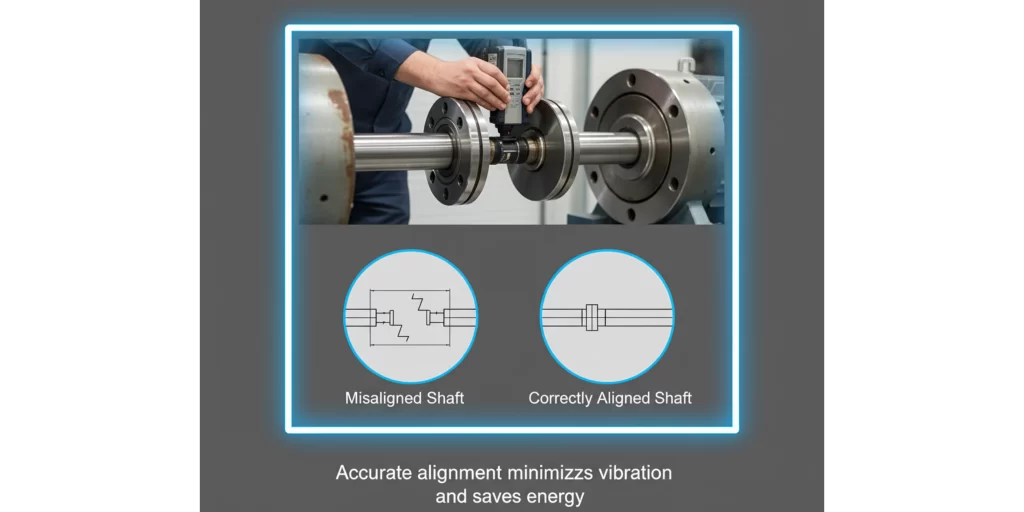

4. Inspect Seals, Gaskets, and Shaft Alignment

Even a small leak or misalignment can create a chain reaction—causing loss of vacuum, vibration, and excessive load on the motor.

Routine actions:

- Check for air or water leaks around mechanical seals, gland packing, and flanges.

- Maintain proper shaft alignment between the pump and motor using laser or dial gauges.

- Replace worn-out gaskets, O-rings, and seals promptly.

Remember: A properly aligned system not only reduces wear but also saves significant energy by lowering friction losses.

Even a small leak or misalignment can create a chain reaction—causing loss of vacuum, vibration, and excessive load on the motor.

Routine actions:

- Check for air or water leaks around mechanical seals, gland packing, and flanges.

- Maintain proper shaft alignment between the pump and motor using laser or dial gauges.

- Replace worn-out gaskets, O-rings, and seals promptly.

Remember: A properly aligned system not only reduces wear but also saves significant energy by lowering friction losses.

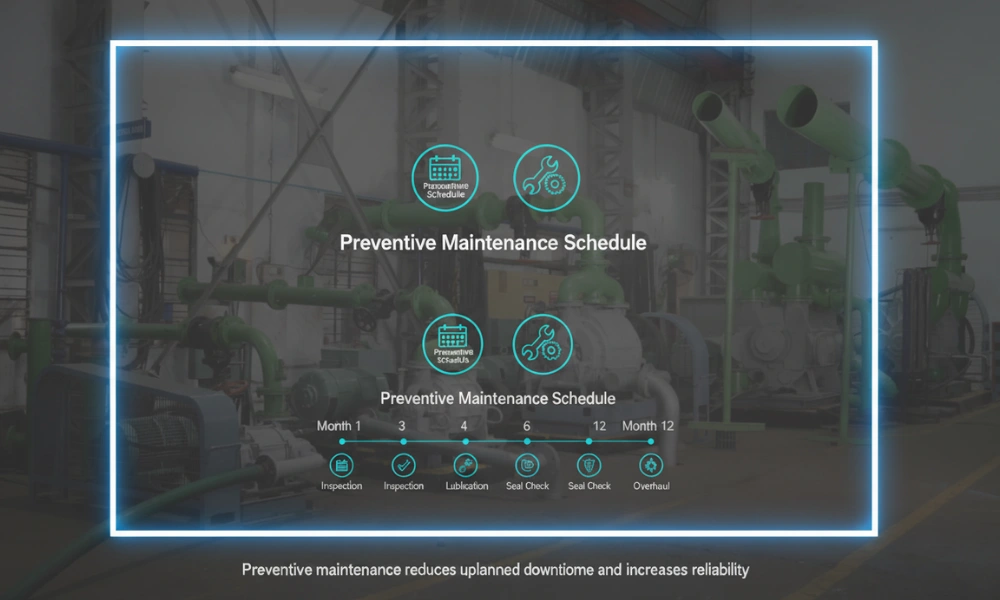

5. Schedule Preventive Maintenance – Don’t Wait for Failure

Reactive maintenance (fixing after failure) leads to unplanned downtime and higher costs. Instead, plan a preventive maintenance schedule based on operating hours and process conditions.

Include in your PM plan:

- Vibration and noise monitoring

- Periodic performance testing (vacuum level vs. power)

- Cleaning of internal passages and impeller inspection

- Verification of electrical parameters (motor load, insulation resistance)

Kakati Advantage: Many of our clients follow Kakati’s Annual Maintenance Program (AMP) – a structured service plan that includes inspection, performance auditing, and training to ensure pumps run at peak efficiency all year round.

Reactive maintenance (fixing after failure) leads to unplanned downtime and higher costs. Instead, plan a preventive maintenance schedule based on operating hours and process conditions.

Include in your PM plan:

- Vibration and noise monitoring

- Periodic performance testing (vacuum level vs. power)

- Cleaning of internal passages and impeller inspection

- Verification of electrical parameters (motor load, insulation resistance)

Kakati Advantage: Many of our clients follow Kakati’s Annual Maintenance Program (AMP) – a structured service plan that includes inspection, performance auditing, and training to ensure pumps run at peak efficiency all year round.

Bonus Tip: Quality from the Start

Even the best maintenance routine cannot compensate for poor design or inferior build quality. That’s why starting with a reliable, well-engineered pump is crucial.

At Kakati Karshak Industries, every Liquid Ring Vacuum Pump is engineered for durability, smooth operation, and low maintenance. With precision machining, dynamically balanced rotors, and high-quality materials, our pumps are built to last—year after year.

Conclusion

Proper maintenance isn’t just about avoiding breakdowns—it’s about optimizing performance, saving energy, and extending equipment life. By following these five simple maintenance steps, industries can boost uptime, reduce costs, and achieve long-term reliability.

When it comes to keeping your vacuum pumps in perfect condition, trust the experts who build them best – Kakati Karshak Industries.