From Paper to Power Plants – Why Every Industry Relies on Liquid Ring Vacuum Pumps

Across the world, industries operate on invisible foundations. Behind the noise of turbines, the constant hum of paper machines, or the quiet efficiency of chemical plants lies an unsung technology—liquid ring vacuum pumps. These systems may not draw attention, but they are indispensable to production lines, ensuring reliability, consistency, and efficiency in sectors as diverse as paper manufacturing, sugar processing, chemicals and power generation.

The Principle Behind Reliability

Liquid ring vacuum pumps are built on a simple yet powerful concept. They use a rotating impeller and a liquid ring to create the vacuum required for industrial processes. Unlike other technologies, this design ensures smooth operation with low vibration, minimal wear and tear, and an ability to handle vapours and condensable gases with ease. The result is a pump system that combines durability with efficiency—qualities every industry depends on.

Power Plants - Efficiency Where It Matters Most

In thermal and nuclear power plants, condenser air extraction is critical to maintaining turbine efficiency. Even minor inefficiencies can translate into massive losses of power and revenue. Liquid ring vacuum pumps are the backbone of these systems, ensuring continuous removal of air and gases from condensers to maintain optimal vacuum levels. Their rugged design, high reliability, and ability to perform under fluctuating loads make them the preferred choice for power plants worldwide.

Paper Mills - Energy Conservation and Process Stability

Paper mills are energy-intensive environments, where every unit of energy saved can lead to significant cost reduction. Liquid ring vacuum pumps play a central role in dewatering and sheet formation, creating the vacuum needed for stable, efficient operations. Modern paper plants increasingly look at energy recovery as a priority, and liquid ring vacuum pumps, with their adaptability and proven reliability, help achieve exactly that.

Chemical and Process Industries - Reliability Under Pressure

Handling corrosive gases, explosive vapours, and high-temperature applications requires pumps that can withstand extreme conditions without compromising safety. Liquid ring vacuum pumps are widely used across chemical and petrochemical plants because of their ability to manage challenging gases, moisture, and temperature variations. Their design naturally resists contamination and ensures steady vacuum pressure, allowing sensitive processes to run without interruption.

Sugar and Food Processing - Clean Operations at Scale

Built for Versatility, Proven by Time

One of the reasons liquid ring vacuum pumps stand apart is their sheer versatility. From handling massive condenser loads in a power plant to supporting delicate dehydration in a food facility, they perform across a wide vacuum range and capacity spectrum. This flexibility is why industries trust them as the “one solution for many challenges.”

Over the decades, manufacturers in India and across the globe have refined these pumps to deliver higher efficiency, better water management, and improved longevity. Today, liquid ring vacuum pumps are not only a choice for reliability but also for sustainability, aligning with industries’ growing focus on reducing carbon footprint and improving resource efficiency.

Conclusion

From paper mills to power stations, from sugar factories to chemical complexes, liquid ring vacuum pumps have become the silent partners of progress. They may not make headlines, but their role is undeniable—driving efficiency, enabling energy recovery, and ensuring reliability in industries that keep the world running.

In every sector where performance cannot be compromised, liquid ring vacuum pumps continue to prove why they remain the trusted standard—quietly powering industries, one process at a time.

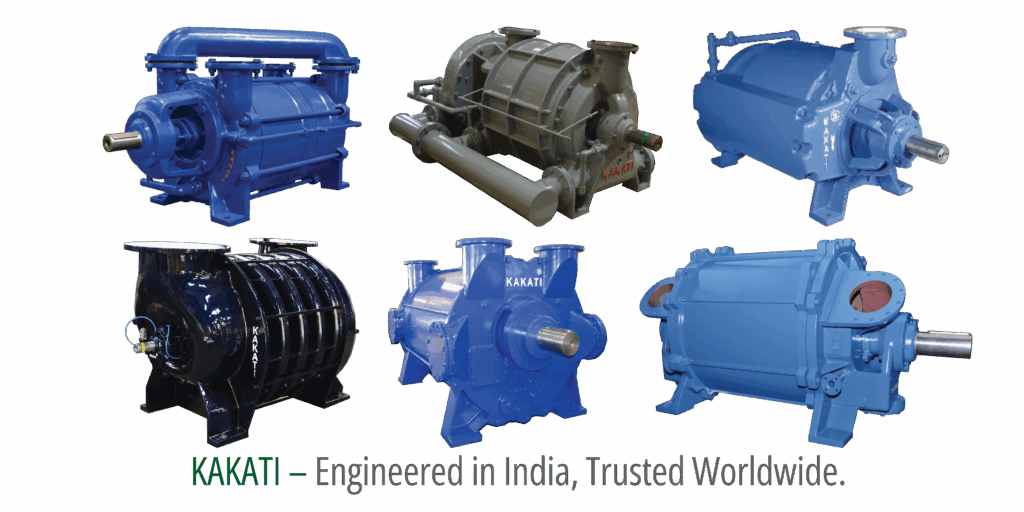

If your operations demand dependable, energy-efficient, and proven vacuum technology, it’s time to explore how Kakati Karshak Industries can deliver solutions built on six decades of expertise. Discover the difference in precision-engineered liquid ring vacuum pumps with Kakati.