Technical Corner

- Home

- Technical Corner

Our Certifications

BS OHSAS 18001 : 2007

ISO 9001 : 2015

ISO 14001 : 2015

CE Certificate

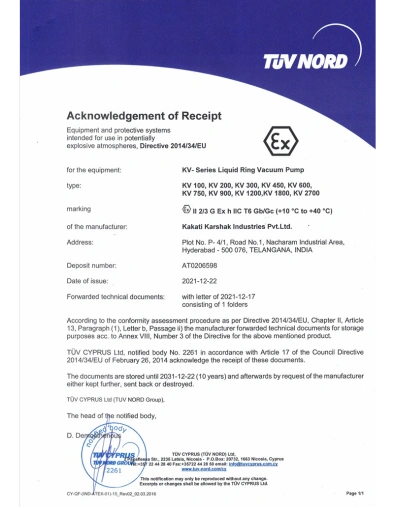

ATEX Certificate

FAQ's

At Kakati Pumps, we specialize in the design and manufacture of liquid ring vacuum pumps and compressors. Our product range includes: Single-stage pumps like the KV-Series, Two-stage pumps such as the KDS-Series, KVT-Series, Energy-efficient pumps like the KEN-Series, High-capacity pumps like the KXL-Series, and Customized vacuum systems for specialized industrial needs. All our products are built for durability, energy efficiency, and ease of maintenance.

A liquid ring vacuum pump works by using a rotating impeller inside a casing partially filled with sealing liquid (usually water). As the impeller spins, a ring of liquid forms and creates sealed spaces that trap and compress gases. At Kakati, our pumps are engineered to ensure maximum efficiency and reliability, even in demanding applications.

Single-stage pumps (like our KV-Series) are ideal for standard vacuum requirements. Two-stage pumps (KDS, KVT-Series) achieve deeper vacuum and are more energy-efficient at lower pressures. Kakati offers both and helps you choose based on your performance and cost goals.

The ‘vacuum level’ refers to the operating pressure your process needs (e.g., in Torr, mbar, or mmHg), while ‘ultimate vacuum’ is the lowest pressure the pump can ideally reach under perfect conditions. At Kakati Pumps, we ensure our specifications list both, ensuring consistent real-world performance.

Consider vacuum level, capacity (m³/hr or CFM), gas/vapour composition, duty cycle, temperature, and material compatibility. Kakati conducts free pre-selection audits to ensure clients get the right match for their process.

Poor quality or improper volume of seal liquid can lead to low vacuum, overheating, vibration, or corrosion. Kakati provides closed-loop seal-water systems and training to prevent such issues.

We recommend: Monthly inspection of seal liquid, Quarterly checks on bearings and clearances, Annual overhauls for continuous duty pumps. Kakati Pumps provides AMC (Annual Maintenance Contracts) to ensure optimal performance.

We at Kakati usually check: Leaks in the inlet or piping, Seal liquid level or flow, Filters or strainers clogging, Impeller-to-casing clearance, Blade, bearing, or motor wear. We also provide a technical helpline and troubleshooting guides.

Liquid ring pumps are better for wet gas, vapours, and condensables — they handle contaminants easily, have fewer moving parts, and run cooler with less maintenance.

Yes. We offer retrofit kits and upgrades that improve efficiency and extend the lifespan of existing systems without major layout changes.

Our vacuum pumps and compressors are trusted by major players in industries such as: Power generation, Paper and pulp, Petrochemicals, Sugar, Mineral extraction, Chemical and fertilizer industries. We serve clients in India and over 20+ countries globally.

The ideal vacuum level depends on your process. For example: Paper and pulp: 50–70 Torr, Power generation: 25–35 Torr, Sugar mills: 100–150 Torr. Our team can conduct vacuum audits and recommend the best solution for your application.

Large industries need pumps with high flow (often thousands of m³/hr) and specific vacuum levels to match processes like evaporators or dewatering. Kakati’s high-capacity KXL series is designed precisely for such heavy-duty applications.

Upgrading to a Kakati energy-efficient model, fixing leaks, and optimizing system design can lead to 20–30% energy savings. We also perform performance audits to identify inefficiencies.

Common energy wasters include leaks, incorrect vacuum level, poor seal liquid management, and inefficient motors. Kakati offers detailed performance audits to measure usage and recommend energy-saving upgrades.

Yes. Concerns include water usage, discharge, sealant disposal, noise, and emissions. Kakati ensures compliance with international standards and offers eco-friendly designs such as water-recirculation systems and low-noise operation.

Kakati Pumps has over 60+ years of experience in vacuum technology, with: A strong in-house R&D team, Custom-engineered solutions, Comprehensive after-sales service, and Proven energy-efficient designs. We’re not just a supplier — we’re a long-term partner focused on performance, efficiency, and support.

Yes. We provide full lifecycle support including: Installation assistance, Performance audits, Preventive maintenance, Refurbishment of old systems, Genuine spare parts supply. Our expert team ensures minimal downtime and optimal operation.

Absolutely. We offer tailor-made solutions based on your process needs — including vacuum range, gas composition, temperature, and more. We also design complete vacuum systems with separators, piping, and instrumentation.

We are headquartered in Hyderabad, India, with manufacturing and service units across the country. We export globally, serving customers in Asia, Africa, the Middle East, and beyond.

Cost depends on capacity, vacuum level, materials, energy efficiency, and customization. Kakati offers transparent quotations detailing pump cost, servicing, and lifecycle value.

Simply fill out the Enquiry Form on our website. Our team will get in touch within 1–2 business days with technical suggestions and pricing.