Advantages of Liquid Ring Vacuum Pumps in Industrial Applications

Vacuum is the invisible force that keeps thousands of industries running — from removing moisture in sugar plants to preventing oxidation in chemical reactors. Among all vacuum pump technologies, Liquid Ring Vacuum Pumps (LRVPs) have become the most trusted workhorse for tough industrial environments.

Whether the gas is dirty… corrosive… full of vapours… or even carries liquid slugs a Liquid Ring Vacuum Pump simply keeps running without complaint.

But why do plants prefer LRVPs over other vacuum solutions like dry screw, rotary vane, or roots blower systems?

Let’s explore the top advantages that make them the industry favorite.

1. Rugged and Reliable for Harsh Processes

LRVPs are specifically designed to handle wet, saturated, and dirty gases that usually destroy other pumps.

- Process gas contains moisture

- Solids or liquid carryover

- Corrosive chemical vapours

No problem — thanks to the liquid ring sealing principle, internal components stay protected and cooled.

Applications Example :

- Sugar industry: vapour with entrained juice droplets

- Chemical plants: acidic/solvent vapours

- Pharma: steam-rich extraction gases

- Power Plants – Ash handling and etc.

2. Handles Liquid Ingestion without Damage :

Unlike mechanical dry pumps.

A Liquid Ring Pump can literally pump liquid along with gas, without failure.

This makes it ideal for:

- Evaporators

- Distillation

- Crystallizers

- Condensation vacuum systems

3.Low Noise & Smooth Operation :

No metal-to-metal contact inside → low vibration

Water cushion effect → silent performance

Operational benefits :

Longer bearing life

Less foundation requirements

Better workplace environment

4.Excellent Cooling for High-Temperature Processes :

The sealing liquid absorbs heat from compression, preventing overheating.

Continuous cooling

Better efficiency at high loads

Stable vacuum under varying conditions

Suitable for :

Power plants

Gas removal from compressors

Hot gas extraction systems, etc.

5. Environmentally Friendly Solution

Fluid-sealed compression means:

Zero oil contamination

No wear particles

No toxic lubricant disposal

With proper sealing liquid recovery, emissions and water usage can be greatly reduced.

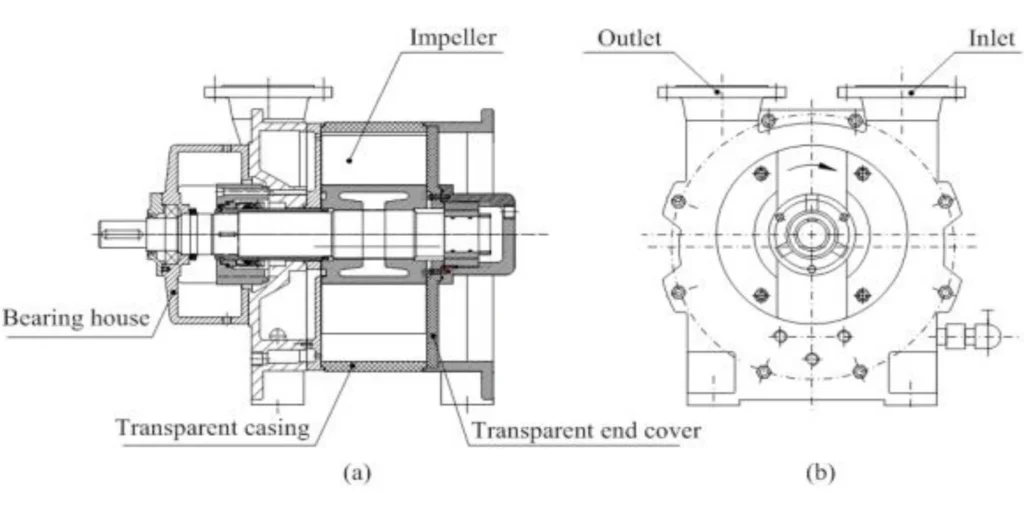

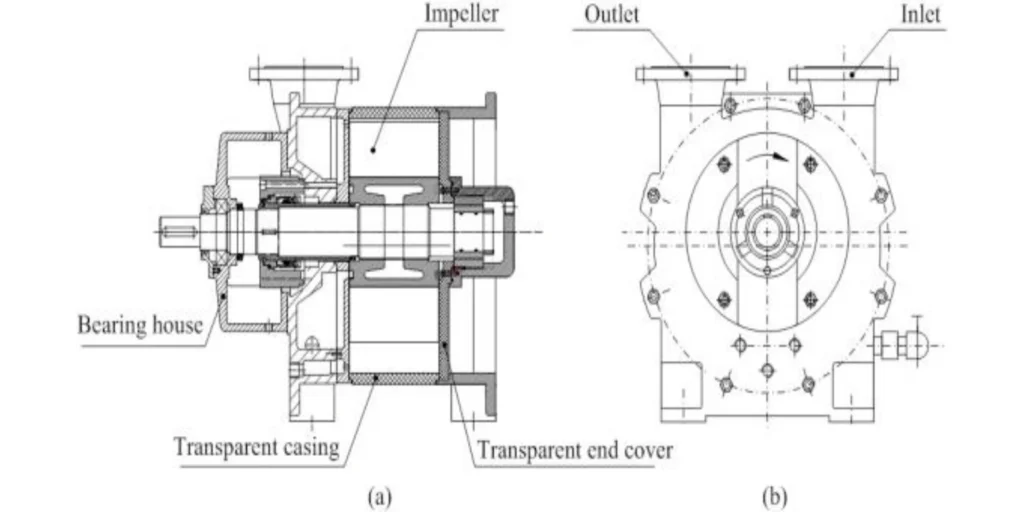

6. Simple Design → Easy Maintenance

Single rotating part — no complex internals like screws or vanes.

Benefits to maintenance teams:

Fewer breakdowns

Quick overhaul

Spares easily available

Perfect for continuous-operation industries (24×7 plants).

One technology — many applications.

7. Versatile Operation across Industries :

| Industry | What LRVP Does |

|---|---|

| Sugar | Vapour handling, pan vacuum & etc. |

| Chemicals | Solvent vapour recovery, Absorption & etc. |

| Pharmaceutical | Distillation & drying & etc. |

| Oil & Gas | Gas compression & flare reduction & etc |

| Food Processing | Deaeration & freeze drying & etc |

| Power Generation | Condenser vacuum & Ash handling & etc. |

Why Choose Liquid Ring Vacuum Pumps?

| Advantages | What It Means for You |

|---|---|

| Handles wet/dirty gases | No risk of pump damage |

| Liquid ingestion tolerance | Ideal for condensate-rich operations |

| Low noise & vibration | Smooth plant operation |

| Continuous cooling | Stable vacuum |

| Eco-friendly | No oil contamination |

| Simple construction | Low lifecycle cost |

| Multi-industry use | High adaptability |

Final Thoughts :

Liquid Ring Vacuum Pumps may look simple — but their performance in harsh industrial environments is unmatched. They deliver reliability, safety, and cost-effectiveness, making them a top choice across global industries.

As industries continue to push for sustainability and uptime, LRVPs remain the most trusted and proven vacuum solution.