Multi-stage Centrifugal Blower

- Home

- Multi-stage Centrifugal Blower

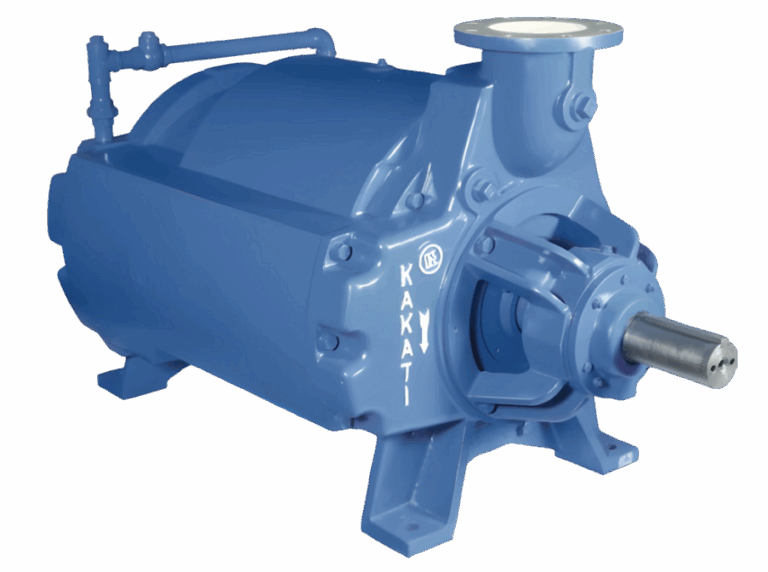

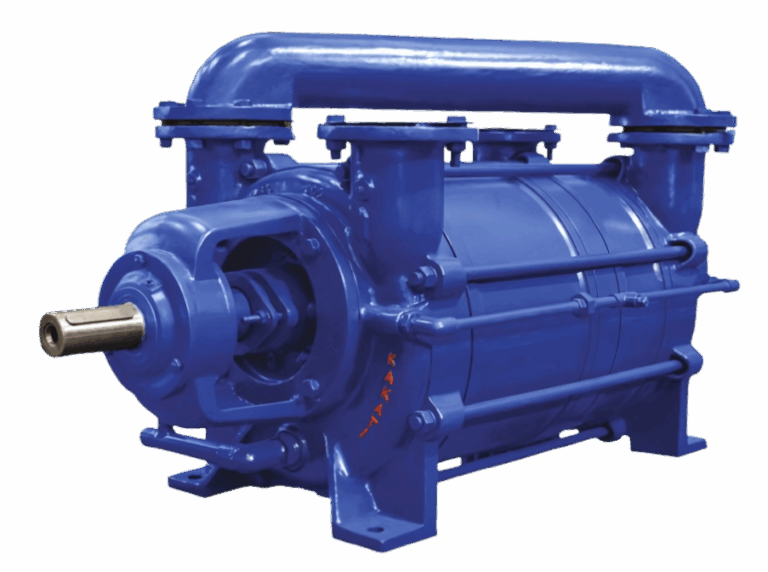

Rugged & Energy Efficient

Multi-stage Centrifugal Blower

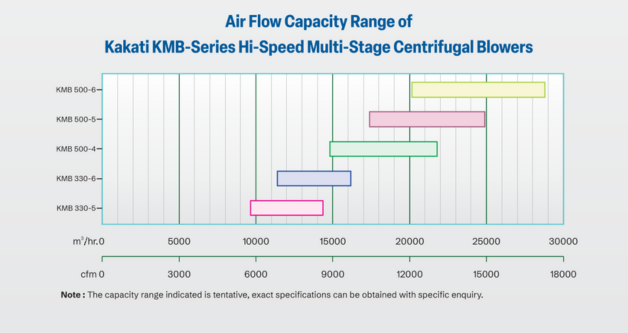

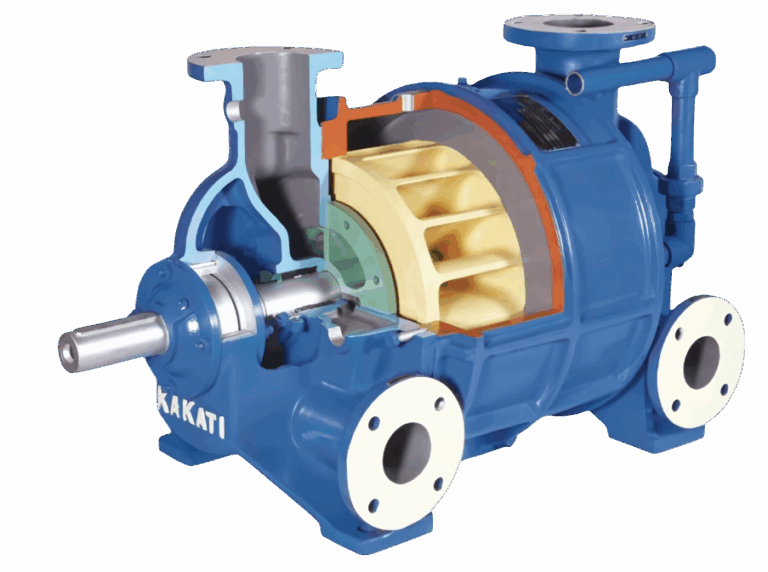

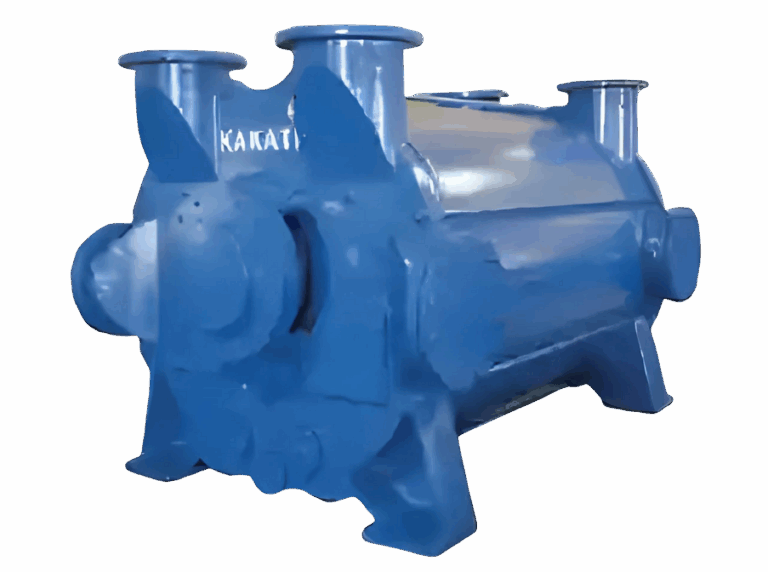

Kakati KMB-Series High Speed Multi-Stage Centrifugal Blowers

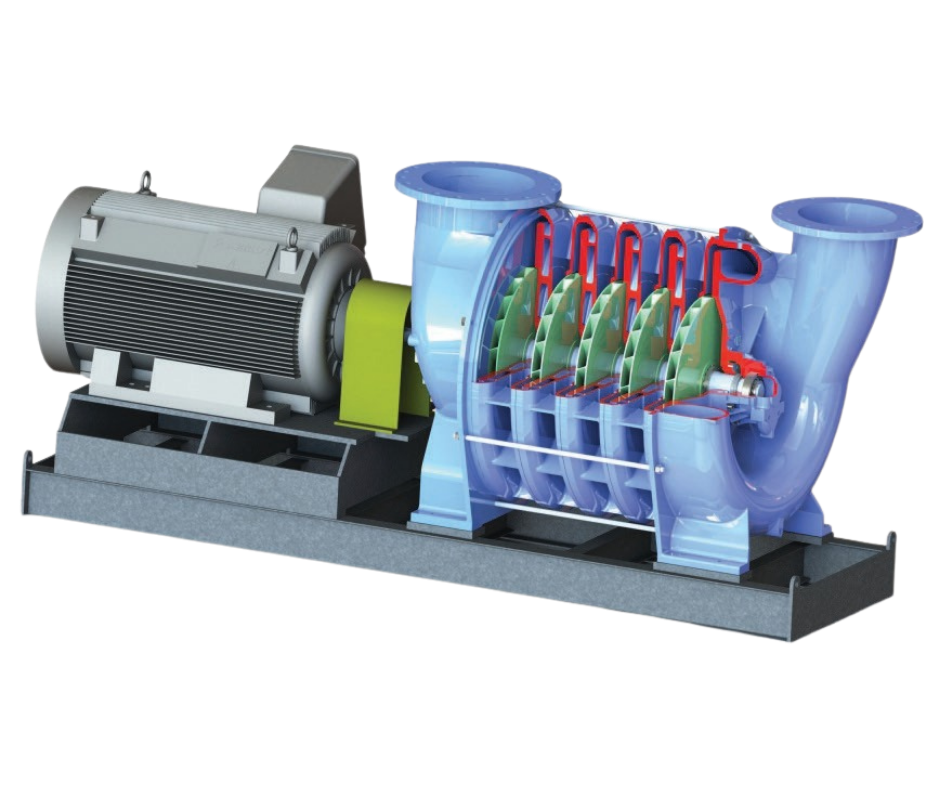

Introducing our KMB Series Blowers, meticulously crafted to address the specific needs of our customers for a robust, efficient, and proven high-speed blower technology. At the heart of the KMB Series is the cutting-edge 3D impeller, precisely designed using Advanced Computational Fluid Dynamics (CFD) simulation.

The product line can be paired with Kakati’s Variable Frequency Drives (VFD), operator interface, a variety of control system options, and blower protection devices to ensure optimum energy efficiency and reliable performance.

Applications include Paper & Pulp, Petrochemical Refineries / Sulfur Recovery, Mining / Flotation, Chemical / Combustion Air for Process Air, and Municipal & Industrial Wastewater Treatment / Aeration.

This innovative approach ensures that the impeller delivers unparalleled adiabatic efficiency of up to 80%, setting a new industry benchmark. The result is a blower that maximizes output while minimizing energy consumption, delivering optimal performance with superior cost-effectiveness.

Basic Specification

| Specification | Details |

|---|---|

| Vacuum range | Up to 450 mmHg |

| Compressor pressure | 2 bar abs |

| Standard construction material | Cast iron, High-grade aluminium impellers |

| Speed | Up to 3600 rpm |

| Capacity | 500 m³/min |

In case of special material of construction, please contact our sales team.

All the castings are tested for surface, mechanical & chemical defects before taken up for machining.

All the rotor-shaft assemblies are dynamically balanced according to ISO 1940-Gr 2.5 standard.

Performance Test:

ISO standards & PTC 10

Vibration:

IS 10186-7 IN.

Noise:

Noise level 85dB at 1mtr. distance.

Bearings:

Standard Ball Bearings minimum L10 bearing life of ten years per AFBMA.

- ► No need for special lubrication pump or forced air cooling.

- ► Multi-stage impeller design ensures stable vacuum up to 450 mmHg & up to 2.2 bar abs.

- ► High-efficiency impellers minimize power consumption and improve energy efficiency.

- ► Designed for reliable 24×7 continuous operation in process plant application.

- ► Efficient handling of humid air and fibers without performance loss.

- ► Low vibration and noise due to dynamically balanced impellers with precision alignment.

- ► Strong housing and casing construction for long service life in industrial conditions.

- ► Oil lubricated ball bearings ensure low maintenance requirement, resulting in reduced downtime & operating cost.

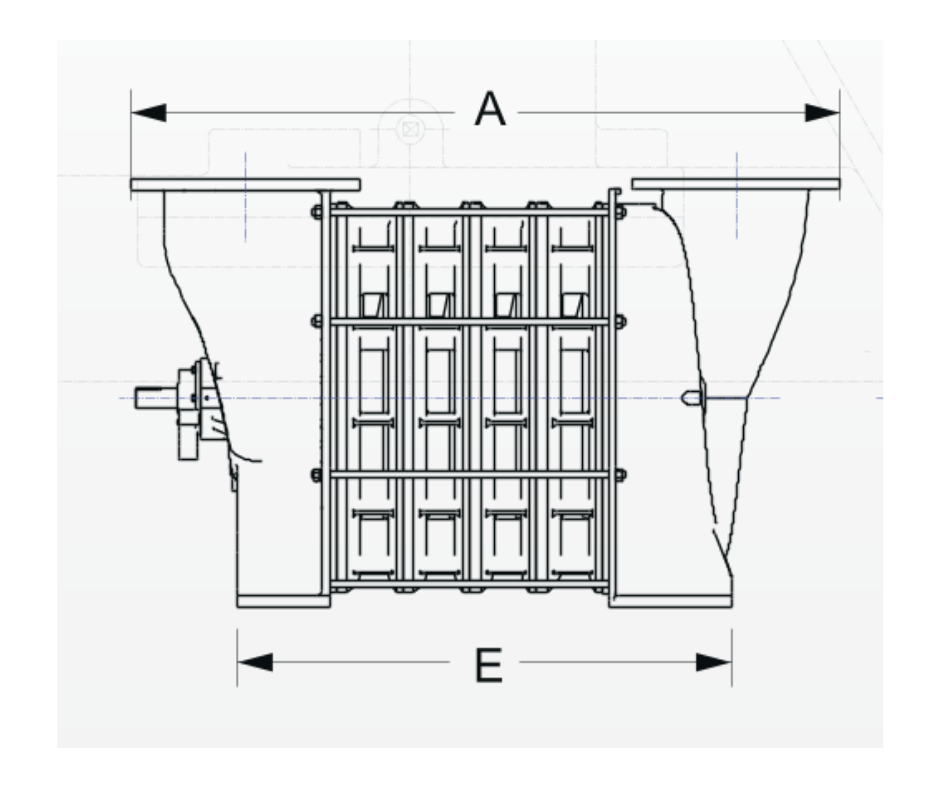

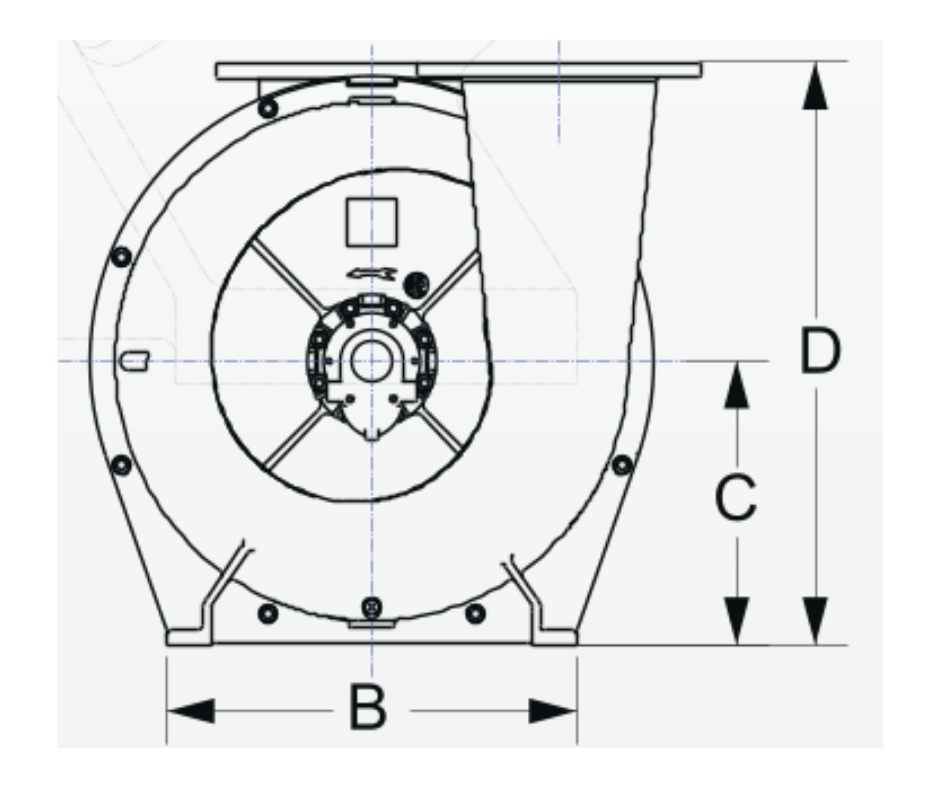

KMB-Series Overall Dimensions:

| Pump Size | Inlet NB | Outlet NB | A | B | C | D | E |

|---|---|---|---|---|---|---|---|

| KMB 330-5 | 500 | 450 | 2170 | 920 | 631 | 1295 | 1505 |

| KMB 330-6 | 500 | 450 | 2370 | 920 | 631 | 1295 | 1705 |

| KMB 500-4 | 600 | 500 | 2665 | 1150 | 1020 | 1550 | 1660 |

| KMB 500-5 | 600 | 500 | 2920 | 1150 | 1020 | 1550 | 1970 |

| KMB 500-6 | 600 | 500 | 3175 | 1150 | 1020 | 1550 | 2615 |

Note: All dimensions are in ‘mm’ & subject to change without prior notice.