The Hidden Hero of Liquid Ring Vacuum Pumps — Shaft Sealing Explained Simply

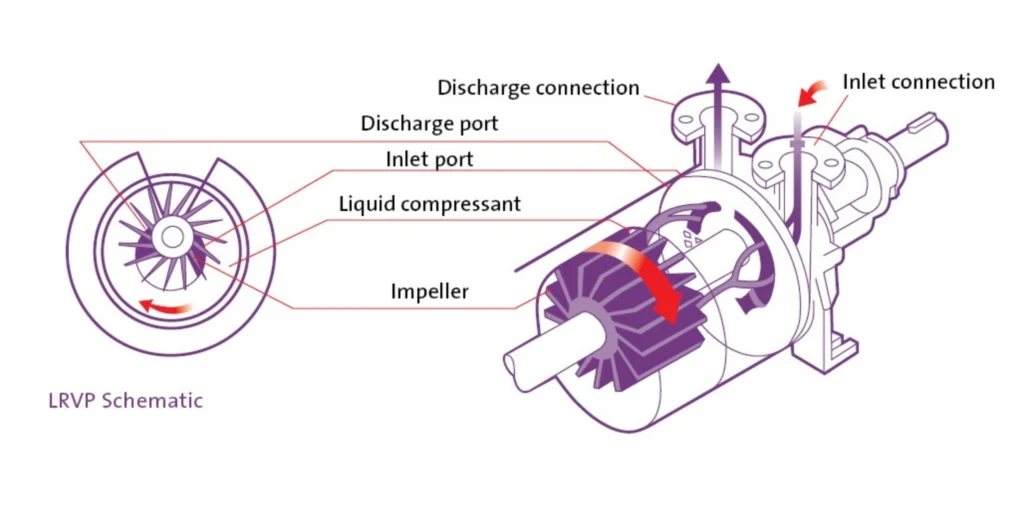

What Really Happens Inside a Liquid Ring Vacuum Pump

Every Liquid Ring Vacuum Pump (LRVP) works on a simple idea — an impeller rotates inside a casing partially filled with liquid (usually water). As it spins, cavities are formed and collapsed, creating suction that pulls gases and vapours from the system.

But there’s one critical spot that most people overlook — the shaft. This rotating shaft must pass through the casing, and that’s where air leakage can sneak in. Even a small leak can drop vacuum levels, consume more power, and shorten the pump’s life.

That’s why shaft sealing is not just a part — it’s the unsung hero that keeps everything under control.

Types of Shaft Sealing in LRVP’s :

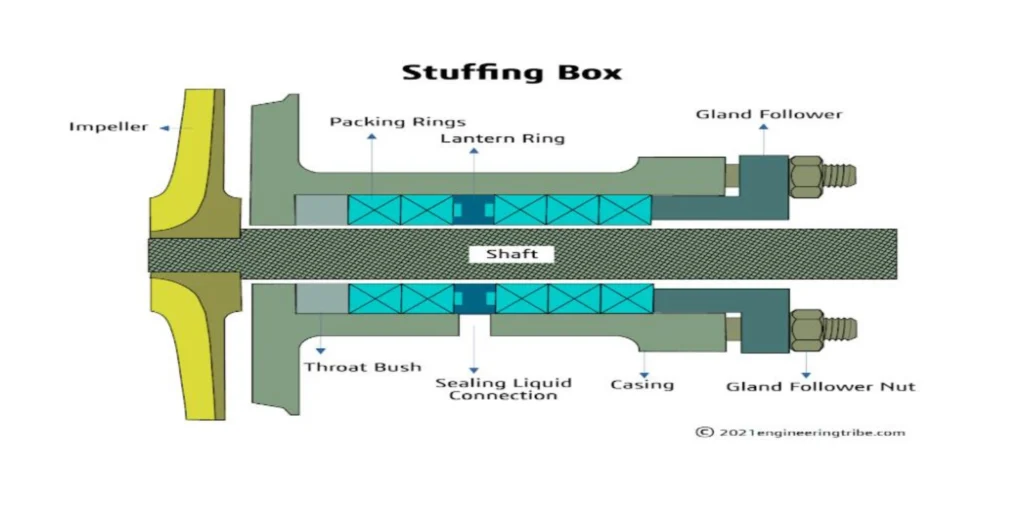

1. Gland Packing (The Classic Workhorse)

This is the oldest sealing method — simple, reliable, and low-cost. It uses soft rings (made from graphite, PTFE, or synthetic fiber) wrapped around the shaft and compressed to block air from entering.

Pros:

Economical

Easy to replace

Proven design

Cons:

Needs periodic tightening

Allows minor leakage

Not ideal for clean or hazardous operations

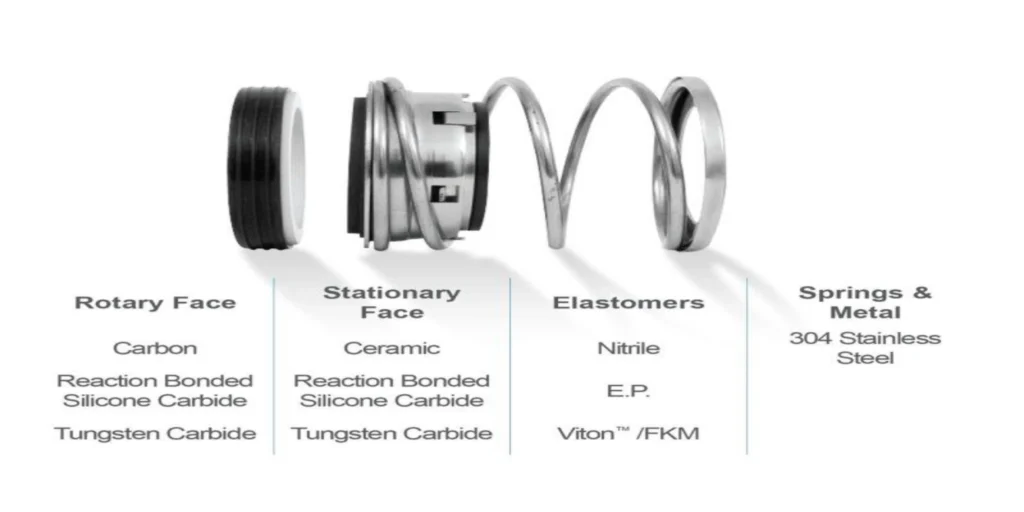

2. Mechanical Seal (The Modern Solution)

A mechanical seal replaces the packing rings with two ultra-flat surfaces:

One rotates with the shaft

One stays fixed to the casing

These faces are pressed together by a spring and a thin film of liquid that keeps them cool and lubricated. This setup gives almost zero leakage and longer life.

Pros:

Clean

Efficient

Long-lasting

Cons:

Slightly higher initial cost

Needs correct installation

3. Labyrinth Seal (The Non-Contact Guardian)

This seal doesn’t touch the shaft — instead, it uses a maze-like path that restricts air entry.

No friction, no wear — just smart engineering.

Perfect for systems where a little leakage is fine and sealing fluid is unwanted.

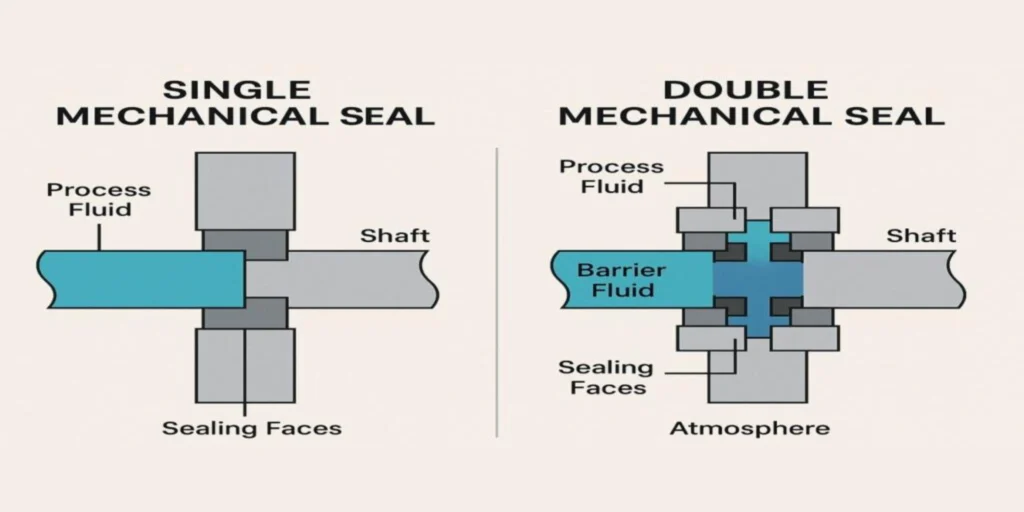

Single vs. Double Mechanical Seal — The Big Difference

| Feature | Single Mechanical Seal | Double Mechanical Seal |

|---|---|---|

| Seal Faces | One pair (rotating + stationary) | Two pairs with barrier fluid between |

| Leakage | Negligible, but visible | Virtually zero |

| Cooling | Cooled by process liquid | Cooled by separate barrier fluid |

| Applications | General gases, clean vapours | Corrosive, toxic, or high-pressure media |

| Maintenance | Simple and low-cost | More complex but safer and longer-lasting |

| Cost | Economical | Higher, but worth it for critical use |

In short:

Go for Single Mechanical Seal when minor leakage isn’t an issue

Choose Double Mechanical Seal for chemical or hazardous duties — where safety, containment, and reliability matter most

How a Double Mechanical Seal Works

Imagine two seals arranged back-to-back with a thin layer of barrier fluid between them.

This fluid — under slightly higher pressure than the vacuum side — forms a protective cushion.

When the shaft rotates:

The barrier liquid keeps both seals cool

It stops gases from escaping or air from entering

It ensures absolute containment — a must for handling toxic or corrosive vapors

Why Double Seals Are Ideal for Chemical Industries

In the chemical industry, safety and reliability are everything.

LRVPs often handle vapors like acids, solvents, or hazardous gases — a tiny leak could be dangerous or costly.

That’s where double mechanical seals shine:

They completely isolate the process gas from the atmosphere

They improve reliability under tough operating conditions

They extend the service life of both seal and pump

When paired with proper barrier fluid and cooling, they offer unmatched performance in harsh environments.

Choosing the Right Seal — Smart Tips

Know your process fluid (clean, dirty, corrosive, or toxic?)

Check your operating temperature and vacuum range

Ensure spare availability and ease of service

Follow proper installation and alignment

Always remember — the best seal is the one that fits both the application and the operator’s maintenance ability

The Real Impact of a Good Seal

A properly designed and maintained shaft seal doesn’t just prevent leakage — it improves the entire performance of the vacuum system.

It helps maintain steady vacuum levels, reduces energy loss, protects bearings and internal components, and ensures a cleaner, safer working environment.

In other words — when your seal is strong, your system is strong.

Final Thought

In every Liquid Ring Vacuum Pump, a number of components work together — impeller, casing, motor, bearings, etc.

But the true performance lies in the small, often unnoticed seal that guards the heart of the system.

It’s a perfect example of how even the smallest component can have the biggest impact.

So next time your vacuum pump runs smoothly without a drop of leakage, give a little credit to the shaft seal — the silent protector behind the performance.