What Happens During a Liquid Ring Vacuum Pump Performance Audit – Step by Step

Liquid Ring Vacuum Pumps (LRVPs) are widely used in power plants, paper mills, chemical plants, refineries, and vacuum systems where reliability is critical. Over time, changes in process conditions, wear, and operating practices can significantly impact pump performance.

A Liquid Ring Vacuum Pump Performance Audit helps identify hidden losses, inefficiencies, and improvement opportunities—often without replacing the pump.

Let’s walk through what actually happens during a performance audit, step by step.

Step 1: Understanding the Application & Design Conditions

The audit begins with a clear understanding of:

- Pump model, capacity, speed, and drive arrangement

- Original design vacuum and capacity

- Application (condenser air evacuation, vacuum filtration, paper machine, etc.)

- Gas composition (air, vapour, non-condensable)

- Seal water flow rate and inlet temperature

👉 This step establishes the benchmark against which current performance will be evaluated.

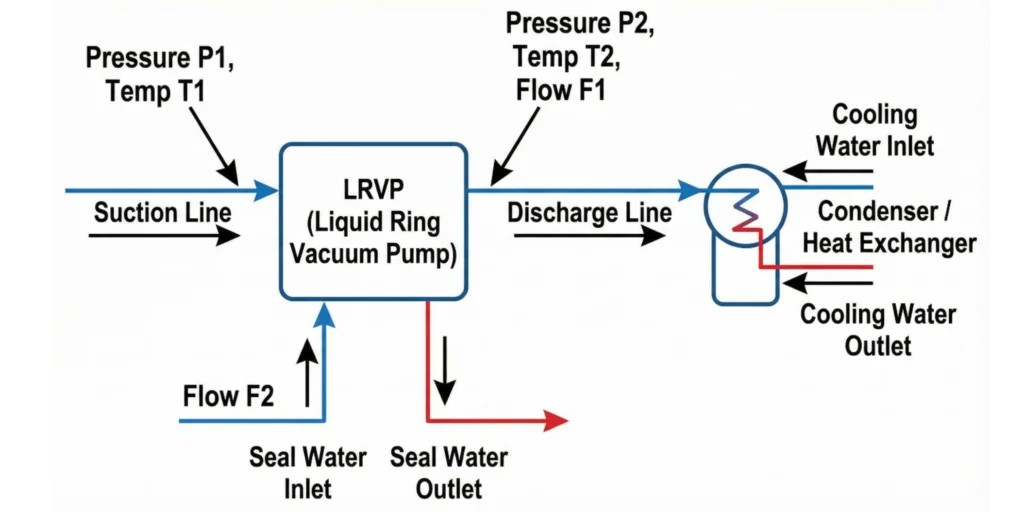

Step 2: Review of Operating Parameters

Next, actual operating conditions are recorded:

- Suction vacuum (mbar(a) or mmHg)

- Discharge pressure

- Seal water inlet and outlet temperatures

- Seal water quality and flow

- Motor power consumption (kW)

- Pump speed (rpm)

Any deviation from design conditions is noted, as LRVP performance is highly sensitive to seal water temperature and pressure.

Step 3: Physical Inspection of the Pump & System

A visual and mechanical inspection is carried out to identify:

- Excessive vibration or abnormal noise

- Leakage from shaft seals or casing

- Condition of bearings, coupling and pulleys alignment

- Scaling, corrosion, or erosion inside the pump

- Piping layout, restrictions, and drain arrangements

👉 Many performance losses are caused not by the pump itself, but by system-level issues.

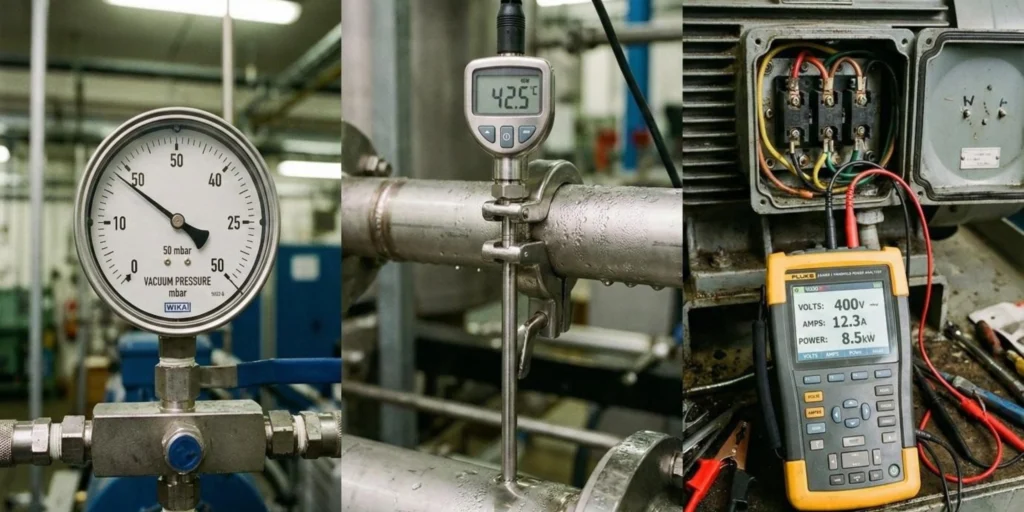

Step 4: Measurement of Actual Pump Performance

During this step, on-site measurements are taken to assess:

- Actual air or gas handling capacity

- Achieved vacuum versus expected vacuum

- Power drawn at different operating points

- Stability of vacuum under load changes

These readings help determine whether the pump is:

- Operating underloaded

- Overloaded

- Flooded with excess seal water

- Starved due to high seal water temperature

Step 5: Seal Water System Evaluation

Since seal water is the heart of an LRVP, special attention is given to:

- Seal water source (fresh, cooling tower, closed loop)

- Temperature rise across the pump

- Adequacy of seal water flow

- Effectiveness of heat exchangers or condensers

👉 Even a 5–10°C increase in seal water temperature can cause a significant drop in vacuum performance.

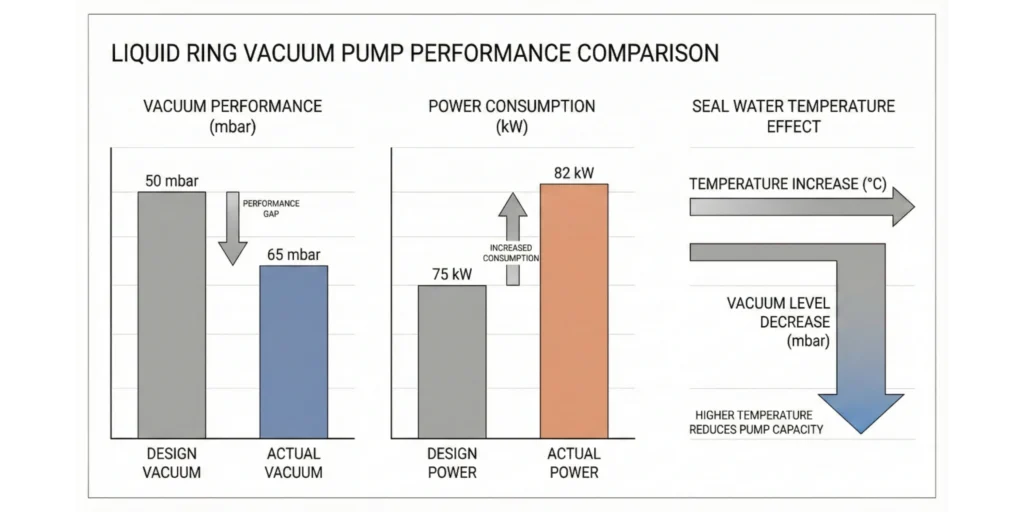

Step 6: Identification of Performance Losses

Based on collected data, losses are categorized as:

- Mechanical losses (wear, clearances, bearings)

- Thermal losses (high seal water temperature)

- Hydraulic losses (incorrect flow, piping restrictions)

- Operational losses (running far from design point)

This step pinpoints why the pump is not delivering its expected performance.

Step 7: Energy Efficiency & Power Consumption Analysis

The audit also evaluates:

- Specific power consumption (kW per m³/min)

- Comparison with design and best-practice values

- Potential energy savings through optimization

In many cases, simple changes like seal water temperature control or speed reduction can lead to noticeable power savings.

Step 8: Recommendations & Improvement Plan

Finally, a detailed audit report is issued with:

- Current vs design performance comparison

- Identified root causes

- Corrective actions (operational, mechanical, or system upgrades)

- Expected performance improvement and energy savings

Recommendations may include:

- Seal water optimization

- Internal refurbishment

- System piping modifications

- Upgrading to high-efficiency LRVP or alternative technology

Why a Performance Audit Matters

A Liquid Ring Vacuum Pump Audit Helps You:

Restore lost vacuum capacity

Reduce power and water consumption

Improve system reliability

Avoid unplanned shutdowns

Extend pump life

Most importantly, it enables data-driven decisions instead of trial-and-error maintenance.

Final Thought

A Liquid Ring Vacuum Pump Performance Audit is not just a check—it’s a health assessment of your entire vacuum system. Regular audits ensure your system operates efficiently, reliably, and economically throughout its life cycle.