Why Your Pump’s Efficiency Drops Over Time? And How To Fix It – Every Pump Has A Story

When a new pump begins its duty in a plant — whether it is a sugar mill, chemical reactor, or effluent system — it runs at its best: smooth suction, steady flow, and minimum vibration. However, a year later, the story changes. The vacuum does not hold, the motor draws more current, and you start hearing that faint, unfamiliar sound.

You might think the pump is “getting old.” However, in reality, it is simply getting tired — from wear, water quality, air leaks, and a few human mistakes.

So let’s explore, in detail, why pumps lose their efficiency over time, what exactly happens inside, and how you can bring them back to their original performance — sometimes even better than new.

1. The Slow Killer – Internal Wear of Components

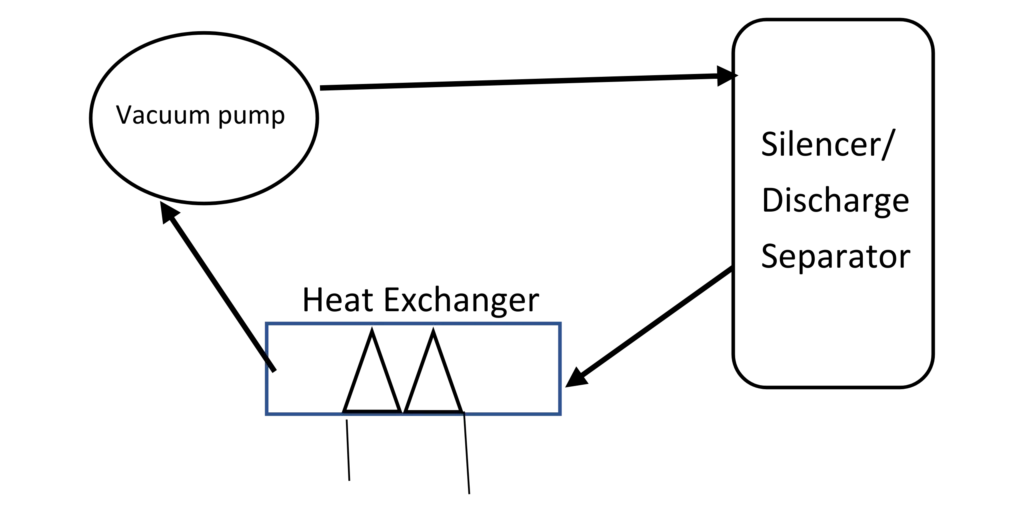

Inside a Liquid Ring Vacuum Pump, the impeller spins at high speed through a thin film of water to create suction.

A thin layer of water forms a liquid ring that seals and compresses the gas. This liquid is both a friend and an enemy — it’s essential for vacuum, but it also causes gradual erosion.

What Actually Happens :

Over thousands of hours of operation:

The impeller tips get eroded by fine particles or cavitation

The end plates wear down where gas enters and leaves

The casing loses its original surface smoothness

Even a clearance increase of 0.3 mm between impeller and port plate can reduce the vacuum level by 5–10%.

How to Fix It :

Recheck internal clearances every 1–2 years

Replace impellers that show pitting or metal loss

Ensure proper water quality to reduce abrasion

Use stainless steel or bronze components if handling corrosive vapours

2. The Invisible Threat – Poor Seal Water Quality

The seal water is the life of a liquid ring pump. It seals, cools, and absorbs heat of compression.

But when the water itself becomes contaminated, it starts damaging the pump silently.

The Damage It Does :

Scaling: Hard water forms lime-scale on surfaces, reducing effective volume

Corrosion: Dissolved gases and salts attack the metal surfaces

Temperature rise: Warm water reduces gas condensation, lowering vacuum

In sugar and chemical plants, poor seal water is one of the top reasons for pump efficiency loss.

How to Fix It :

Always use filtered or soft water

Keep the seal water temperature below 30°C

Install a recirculation system with heat exchanger and filter wherever required

Flush the system weekly to remove sediment

Seal water with high dissolved solids (TDS > 500 ppm) not only reduces performance but can shorten pump life by 30%.

3. The Silent Leak – Air Ingress

If you have ever wondered why your vacuum doesn’t reach the design value even though the pump sounds normal — suspect air leaks.

Even a tiny hole or loose gasket on the suction line can allow atmospheric air to enter, drastically reducing vacuum levels.

Where It Hides :

Loose flanges or threaded connections

Worn shaft seals

Cracked suction pipelines

Improperly sealed valves or gauges

When air leaks in, the pump must work harder — it compresses more gas, consumes more power, and produces less vacuum.

How to Fix It :

Perform a vacuum hold test — isolate the pump and monitor pressure rise

Use soap bubble test at suspected joints

Apply sealant tapes or replace gaskets

For frequent leaks, consider upgrading to mechanical seals

A 1 mm² air leak at 1 bar can cause a vacuum loss of up to 30 m³/hr, enough to lower performance by 15%.

4. The Misuse – Wrong Operating Conditions

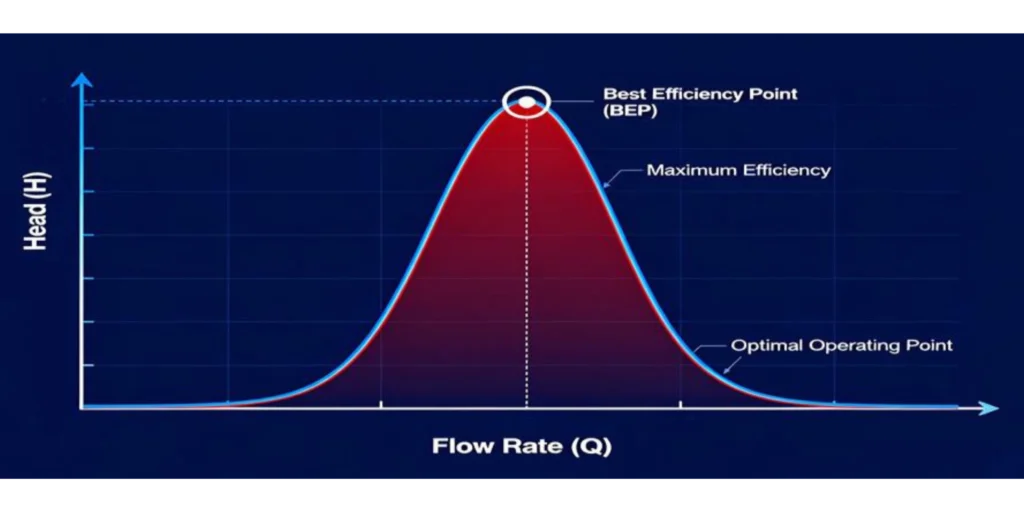

Every pump has a sweet spot — its Best Efficiency Point (BEP).

Running too far from that point is like driving a car in the wrong gear — it still moves, but not efficiently.

Common Mistakes :

Over-speeding: Higher RPM causes cavitation and vibration

Low seal water flow: Inadequate sealing liquid leads to overheating

Operating below design pressure: Causes gas slippage and low vacuum

How to Fix It :

Maintain proper seal water flow rate (as per datasheet)

Check discharge pressure and inlet conditions weekly

Train operators to read and interpret performance curves

Operating even 10% off the design point can waste 8–12% of energy continuously.

5. The Forgotten Routine – Maintenance Neglect

Preventive maintenance isn’t glamorous, but it’s the secret behind every long-lasting pump. Skipping lubrication, ignoring alignment, or delaying seal replacement slowly drains efficiency.

What Fails First :

Bearings lose lubrication → more power, more heat

Shaft seals leak → water and air entry

Alignment drifts → vibration and uneven wear

How to Fix It :

Schedule monthly, quarterly, and annual checks

Record vacuum level, water flow, and ampere load

Realign using laser tools after any dismantling

A pump maintained on schedule can save 15–20% power and extend life by 5 years or more.

6. How to Bring Your Pump Back to Life

If your pump has lost performance, don’t rush to replace it.

Often, it can be rebuilt and re-optimized to perform like new — or even better.

Steps to Rejuvenate Performance :

Dismantle and inspect all rotating parts

Replace worn components with OEM spares

Reset clearances as per manufacturer’s drawing

Clean all ports and internal passages thoroughly

Balance the impeller dynamically before assembly

Realign motor and pump using laser alignment

Test-run with correct seal water flow and temperature

A properly overhauled vacuum pump can regain 90–95% of its original performance.

Conclusion – Efficiency Is a Habit, Not a One-Time Fix

Pump efficiency doesn’t vanish overnight; it fades because of neglect, poor water, or bad habits.

But the good news? It can always be restored.

A little attention to detail, consistent maintenance, and proper training can transform your old pump into a high-performing workhorse again.

Your pump doesn’t need magic — it just needs care, understanding, and a little engineering love.

Keep it clean, keep it cool, and it will reward you with years of reliable, energy-efficient performance.